The Difference Between Laboratory Equipment Maintenance and Qualification

Ted Palashis | June 19, 2019

There are many ways to look at maintenance for your laboratory’s equipment. There is periodic maintenance that is done to ensure that different components aren’t going to fail, rendering the instrumentation unusable. This is the same concept of changing the oil in your car, rotating the tires, replacing the brake pads, and flushing the coolant system. All of these measures are done on predetermined intervals to ensure that each component remains operational. Another way to look at the care taken for your lab’s assets is from the perspective of qualification. Both of these angles are important and necessary, but what’s the difference?

Laboratory equipment qualification is an inspection of a particular asset. It can be compared to having your vehicle inspected. Your emissions system is checked, headlights and turn signals are assessed, and other features of the vehicle are examined to ensure everything works as it should. This is what operational qualification offers for laboratory instrumentation.

Operational qualification (OQ) uses an innovative, multi-platform, harmonized, analytical instrumentation qualification service for different makes and models of chemical analysis systems. With the ability to incorporate existing manufacturer or client protocols, it can be customized to fit the intended use in accordance with USP <1058>. This type of service can be especially beneficial for labs with multiple vendor instrumentation, first-time qualification of newly purchased systems, or the re-qualification of assets after repair or relocation. Protocol administration can be simplified, regardless of manufacturer, with one standard approach for installation qualification (IQ), operational qualification (OQ),performance qualification (PQ), and validations.

Let’s take a closer look at these different types of qualification services .

Laboratory Qualification Services (IQ/OQ/PQ)

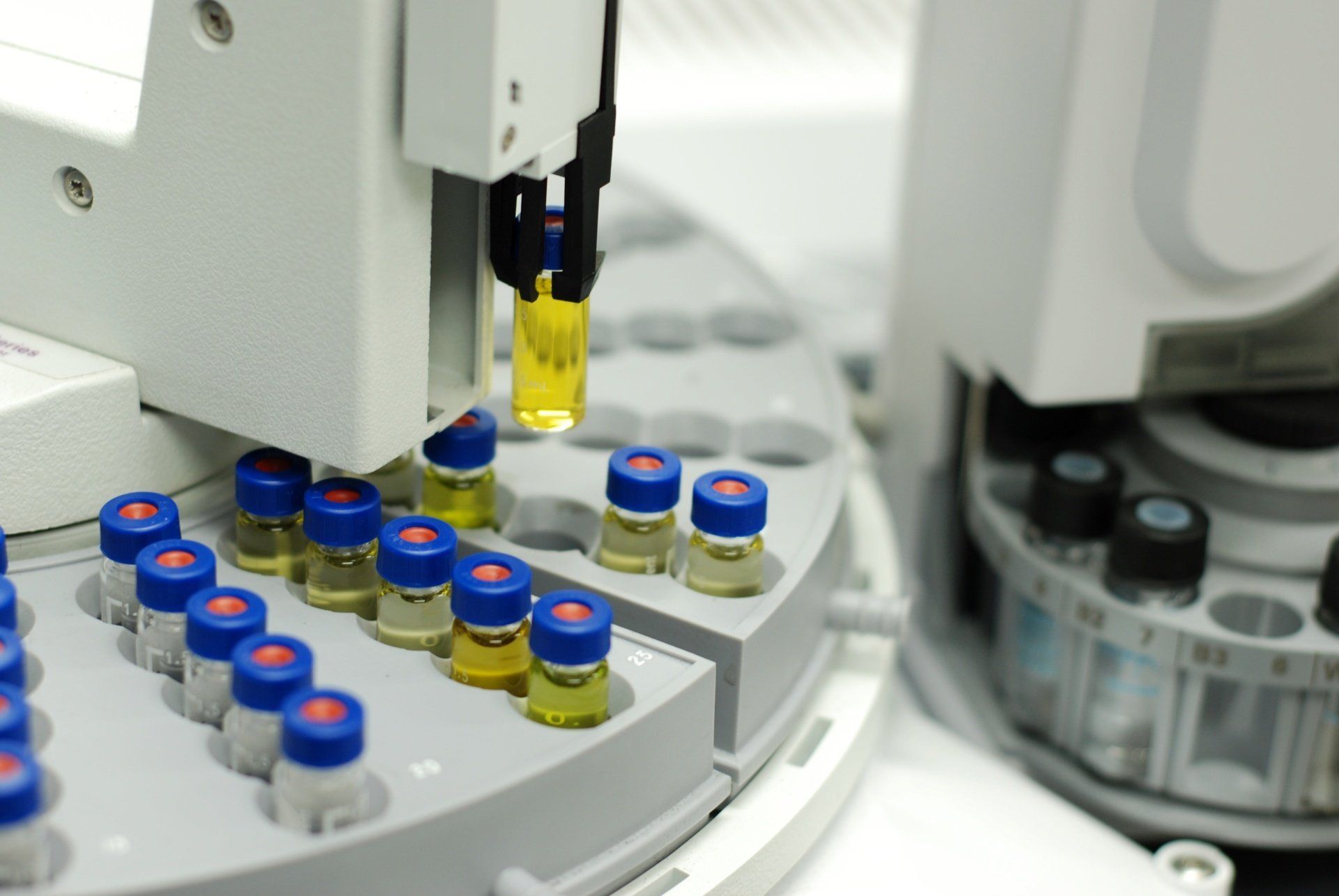

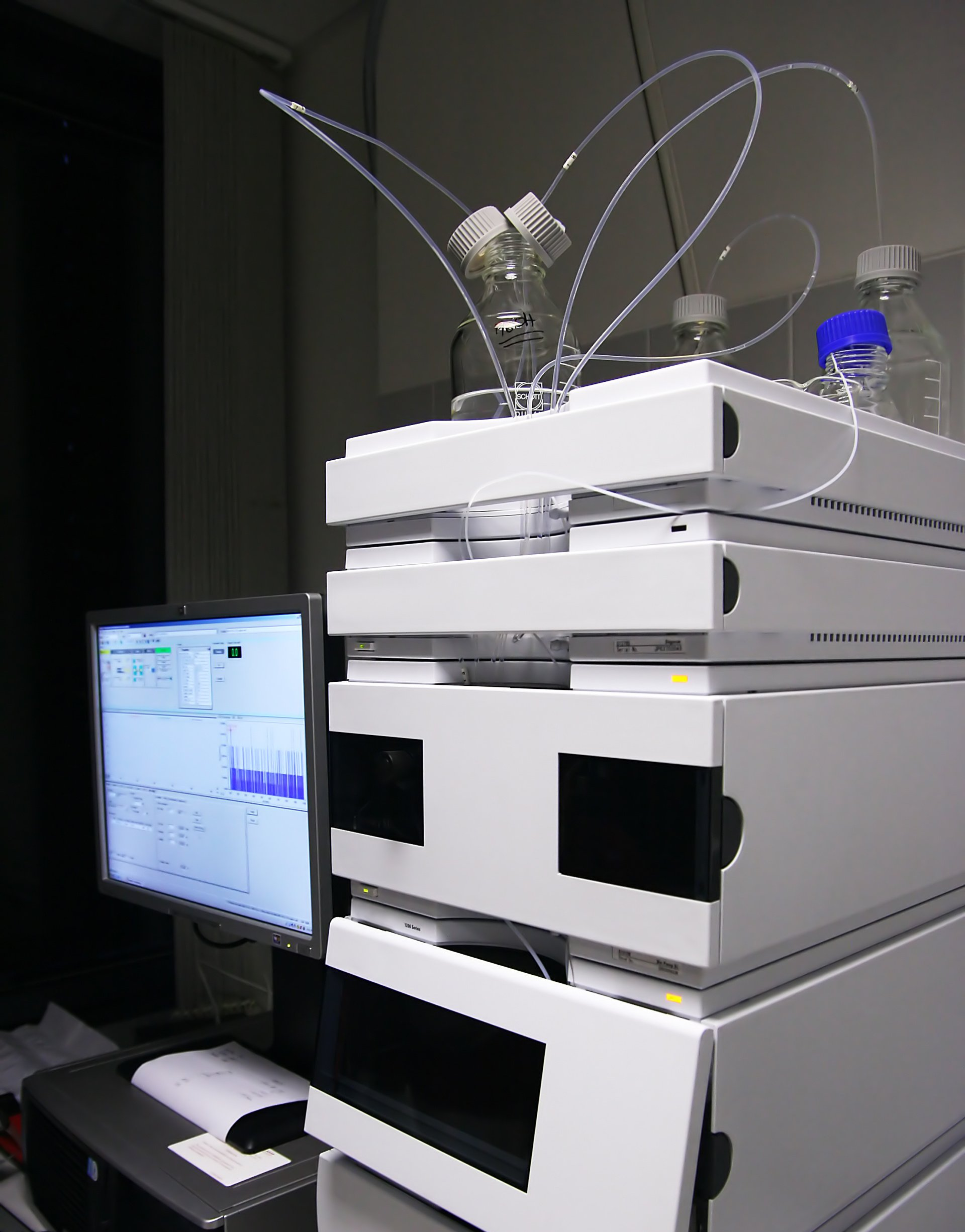

Qualifications performed by an independent outsourced service provider ensures compliance, as opposed to qualification done by an employee of the laboratory. Understanding the requirements of USP<1058> is just as important understanding the mechanics of each device. Each type of qualification (IQ,OQ, PQ) is done routinely. They are also performed for recently purchased HPLC, GC, GCMS, LCMS, and LC-MS/MS. These services are also needed after a replacement, repair, facility or instrument move, and when subject to inspection, audit, or review. What does each of these types of qualification services include?

Installation Qualification (IQ)

Installation qualification of your laboratory’s assets features documented verification that the system’s components and support systems have been correctly and completely installed. IQ is performed following manufacturer and customer requirements, government regulations, and industry standards.

Operational Qualification (OQ)

Operational qualification of laboratory’s instrumentation features documented verification that the system’s components are operating within the manufacturer’s and customer’s requirements, government regulations, and meet industry standards. OQ will establish confidence that the components are capable of consistently operating inside the limits and tolerances that their supported systems require.

Performance Qualification (PQ)

Performance qualification is verified documentation confirming that the total system is performing as intended. PQ establishes that the system, in its entirety, is capable of consistently performing within the required and set limits.

Qualifications are a critical aspect of lab asset management. They are designed to assure that the overall system and its operation are functioning correctly. Another crucial benefit of qualification is to ensure that audit trails accurately capture information.

Overbrook offers all of the above qualification services as well as a total qualification program (TQP). This program provides a choice of qualification options for GLP/cGMP facility and pre-clinical laboratories .

Qualifications, like periodic maintenance, can reduce operational costs, minimize protocol administration burdens, and maintain control with traceability and streamlined support through one provider.

The expert engineers and project managers at Overbrook use their experience, knowledge, and resources to ensure that your assets remain operational and high performing, while your facility reduces costs and downtime.