HPLC Service: Basics of Good Maintenance

Ted Palashis | January 20, 2020

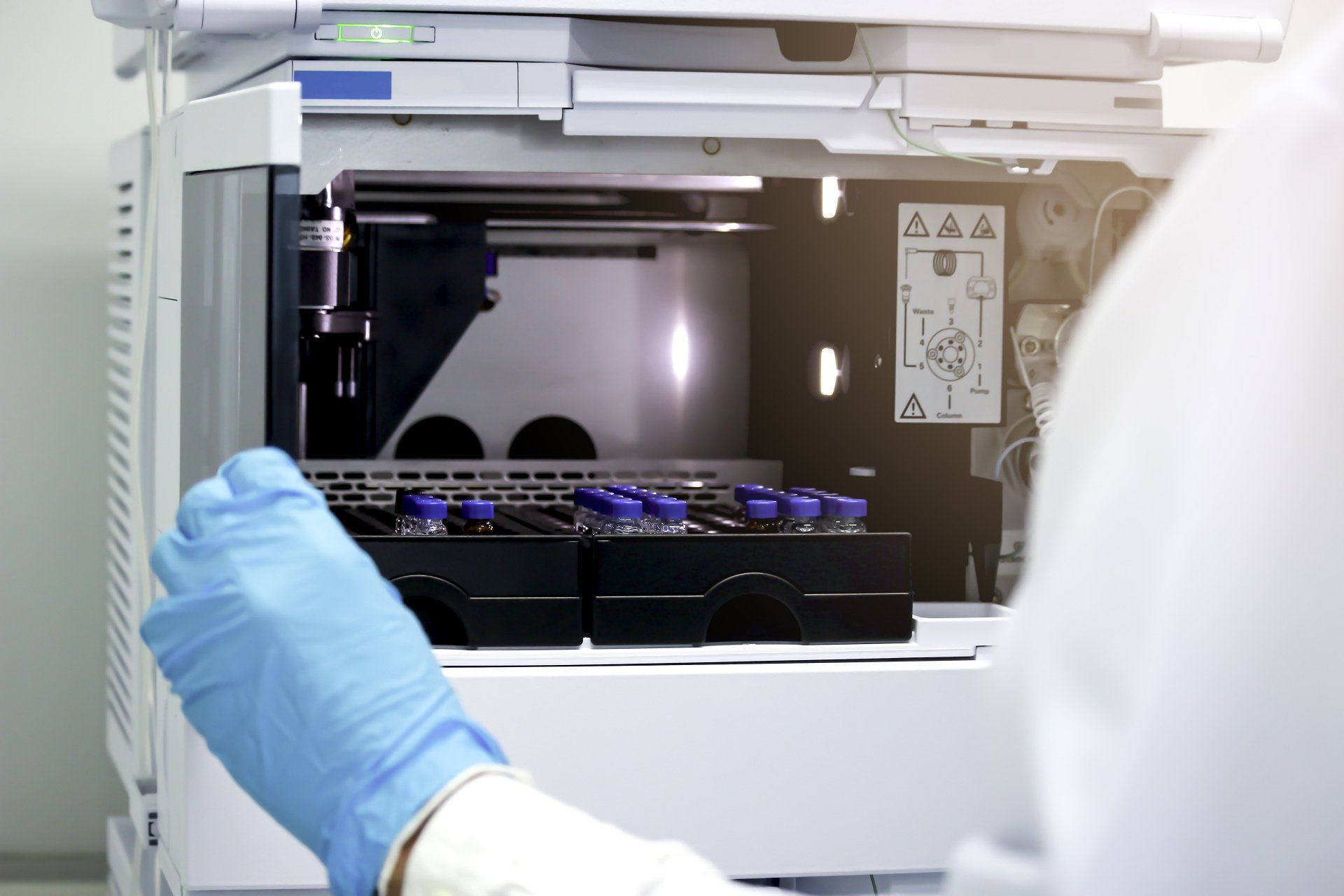

High-performance liquid chromatography offers speed, accuracy, and efficiency for a variety of applications. Through the use of a pump, as opposed to gravity, to force liquid solvent through an absorbent material with different chemicals that are separated as they move at changing speeds, HPLC offers many advantages. However, this instrumentation can only provide the fast, accurate results you need when it’s working correctly. This makes choosing the right HPLC service provider a critical task.

Here are a few basics to keep your HPLC instruments running smoothly and performing well.

Understand Temperature

Different applications will require varying temperatures. Good chromatography is dependent on the analyte’s equilibrium during both mobile and stationary phases. Be sure that the temperature for your desired method is specified.

Replace Your Buffers

Higher system pressure or the detection of an elevated background can be the result of aqueous mobile phases that are contaminated with bacteria, mold, or other debris. Changing these buffers daily can eliminate this possibility.

Use a Guard Column

A guard column can be an inexpensive and simple way to extend the life of an HPLC’s analytical column. Guard columns should be changed periodically to ensure they continue to protect the more expensive and complex analytical column.

Monitor the System Pressure

Pressure is a key ingredient in the HPLC process . It’s important to check your system’s pressure on a daily basis. Of course, the pressure will vary based on the method you’re running, but it shouldn’t be substantially lower, higher, or erratic from day to day. Keep a log of each day’s pressure; this information can be vital when it comes to troubleshooting performance issues.

Troubleshoot Strategically

Instead of making a complete replacement of parts and components, take a systematic approach in order to determine the correct repair, as well as the underlying effect. You may think that making a comprehensive part replacement could save time in the long run, but it can be unnecessarily expensive and still leave you looking for the root cause. Instead of replacing the solvent, precolumn, and detector lamp in one fell swoop, do them one at a time, then retest. Troubleshooting this way can save time, money, and lead to the discovery of what is causing your HPLC issues.

A skilled, experienced service provider can be a resource to not only assist in avoiding these problems to keep you up and running but provide the expertise so you can focus on your science. Overbrook is an HPLC service provider with experience and expertise across many HPLC manufacturers.