HPLC Repair Services: Common Causes of Baseline Noise

Overbrook Liquid Phase Engineering Team | August 31, 2020

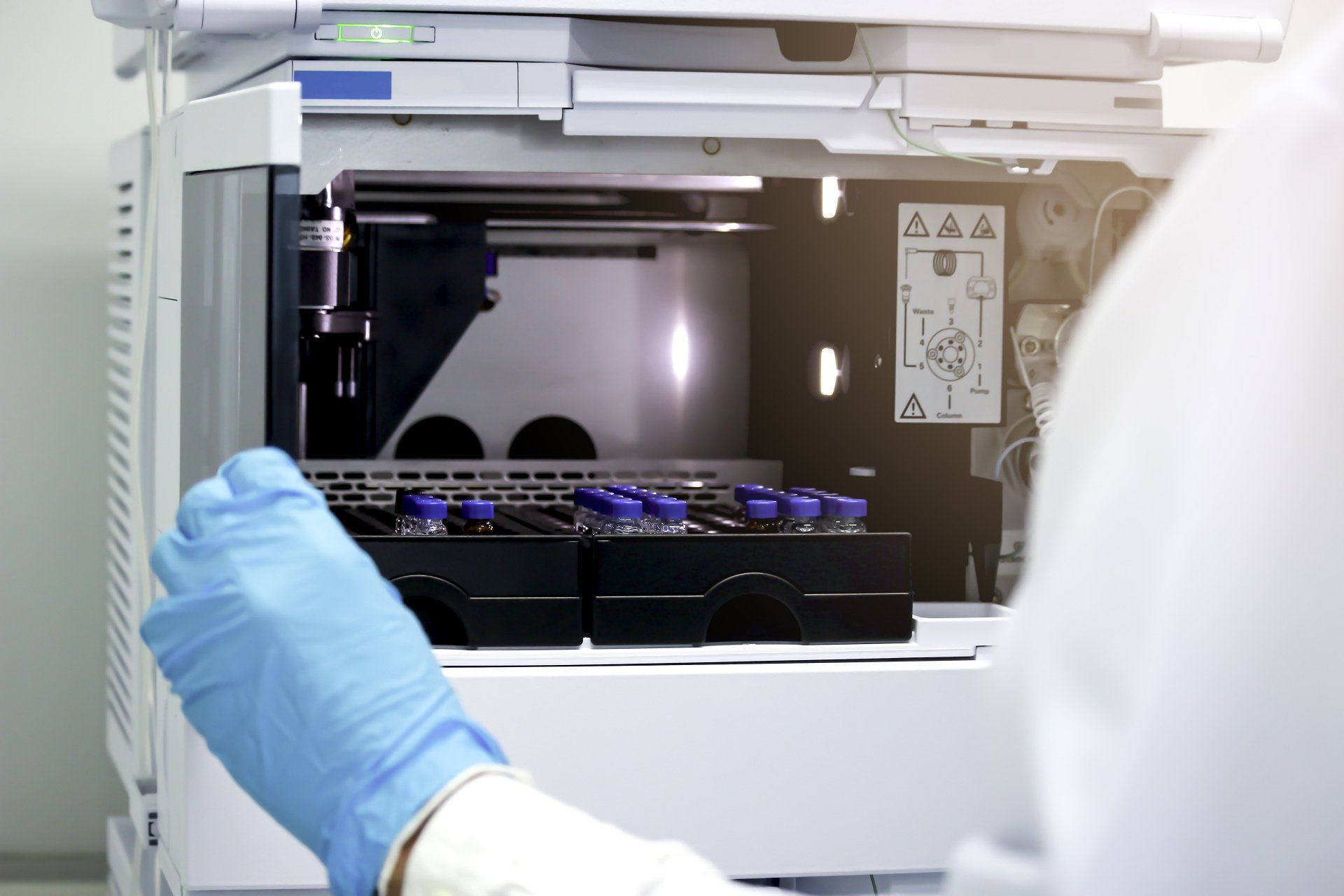

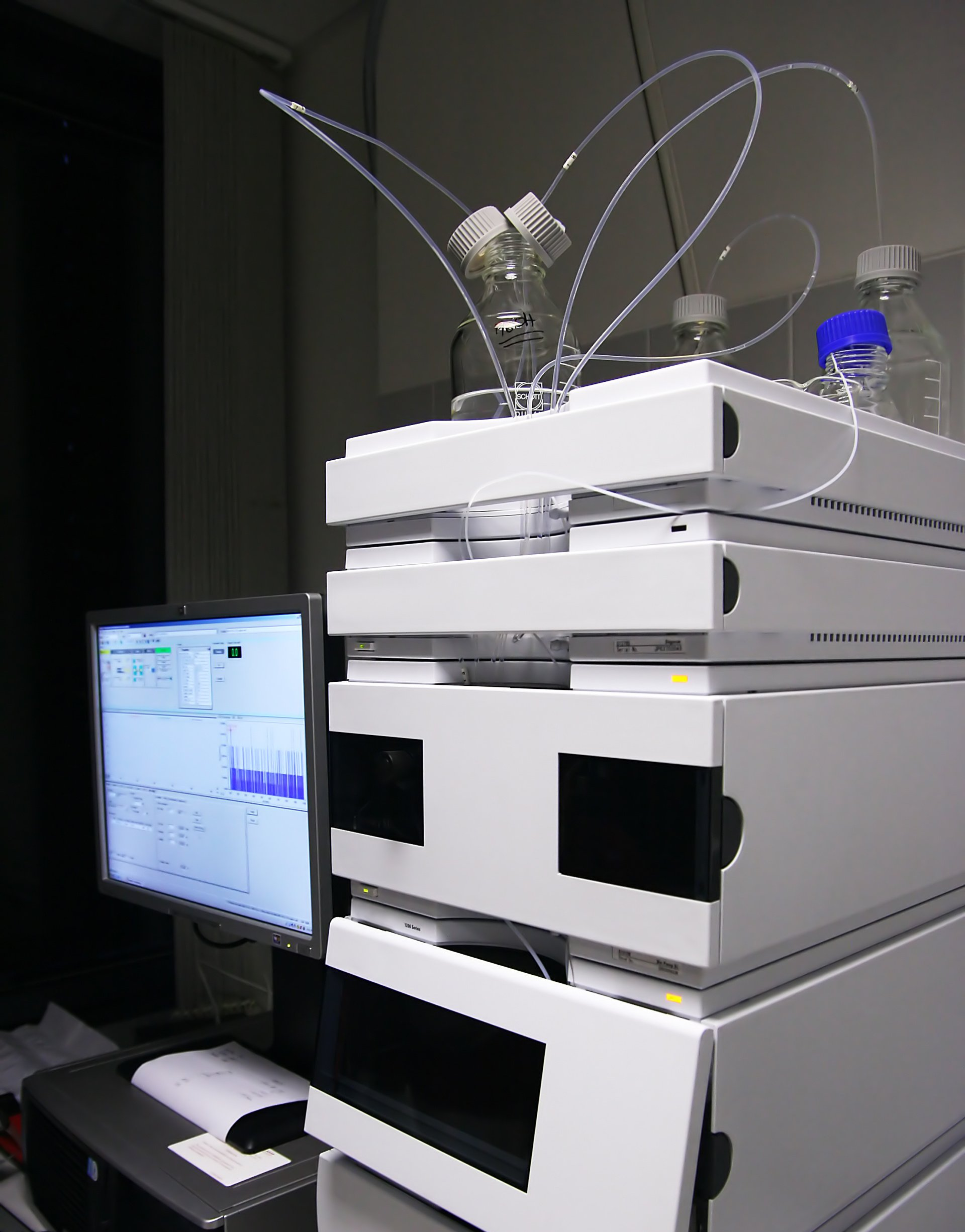

The appearance of your HPLC’s baseline noise is one of the most useful indicators of its overall performance and cleanliness.

The ratio of the detector’s signal response to a specified standard when compared to the background signal variation is known as the “signal to noise ratio.” The background noise is measured over a pre-determined length of baseline. HPLC manufacturers will usually publish their specification for the system’s signal to noise ratio. This is a useful measure of normal background signal variation in the system.

When you notice abnormalities in the baseline noise, it can be attributed to a number of different factors:

HPLC Solvent

High baseline noise can often be attributed to mobile phase contaminants. Noise due to contamination will be most prominent in gradient elution. Phantom peaks can appear as the level of the contaminated solvent is increased. Water is the most common source of solvent contamination. Be sure to only use HPLC grade solvents, and always use an inlet filter on your solvent reservoir lines.

HPLC Degasser

If your system has an in-line degasser, be sure that it is functioning properly. Dissolved air in your solvents can contribute greatly to baseline noise and will appear as pulsations in the baseline that coincide with pump head strokes.

HPLC Pump

If your degasser is functioning properly and your lines are properly primed and pulsations in your baseline are still present, it is possible that your pump requires service. Generally, pump seals should be changed once a year. A pulsating baseline could also be an indication that your pump has a faulty check valve that needs to be replaced.

HPLC Column

Baseline noise can be caused by contaminants washing off from a dirty column or from a column that has degraded due to phase dewetting. If it’s suspected that the column is the source of excessive baseline noise, it should be replaced with a union and the method run without the column while observing the baseline.

HPLC Detector

Every HPLC detector has some amount of noise comprised of electronic noise and stray light which is picked up by the photodiodes within the detector. Elevated levels of baseline noise within the detector can be the result of a lamp deteriorating over time in the form of reduced intensity from a contaminated flow cell or from dirty optics. Some solvents combined with lower wavelength settings will also show elevated levels of baseline noise -- this is normal. For example, MeOH absorbs up to 201nm. Wavelength settings below 220nm will show an increase in noise if this is part of your mobile phase. Buffers also decrease the amount of light hitting the photodiodes, which can increase the baseline noise

Whether your HPLC systems are new or reconditioned; Overbrook can help.