HPLC Service Provider: Ideas to Get the Most Out of Your High Performance Liquid Chromatography

Ted Palashis | January 24, 2020

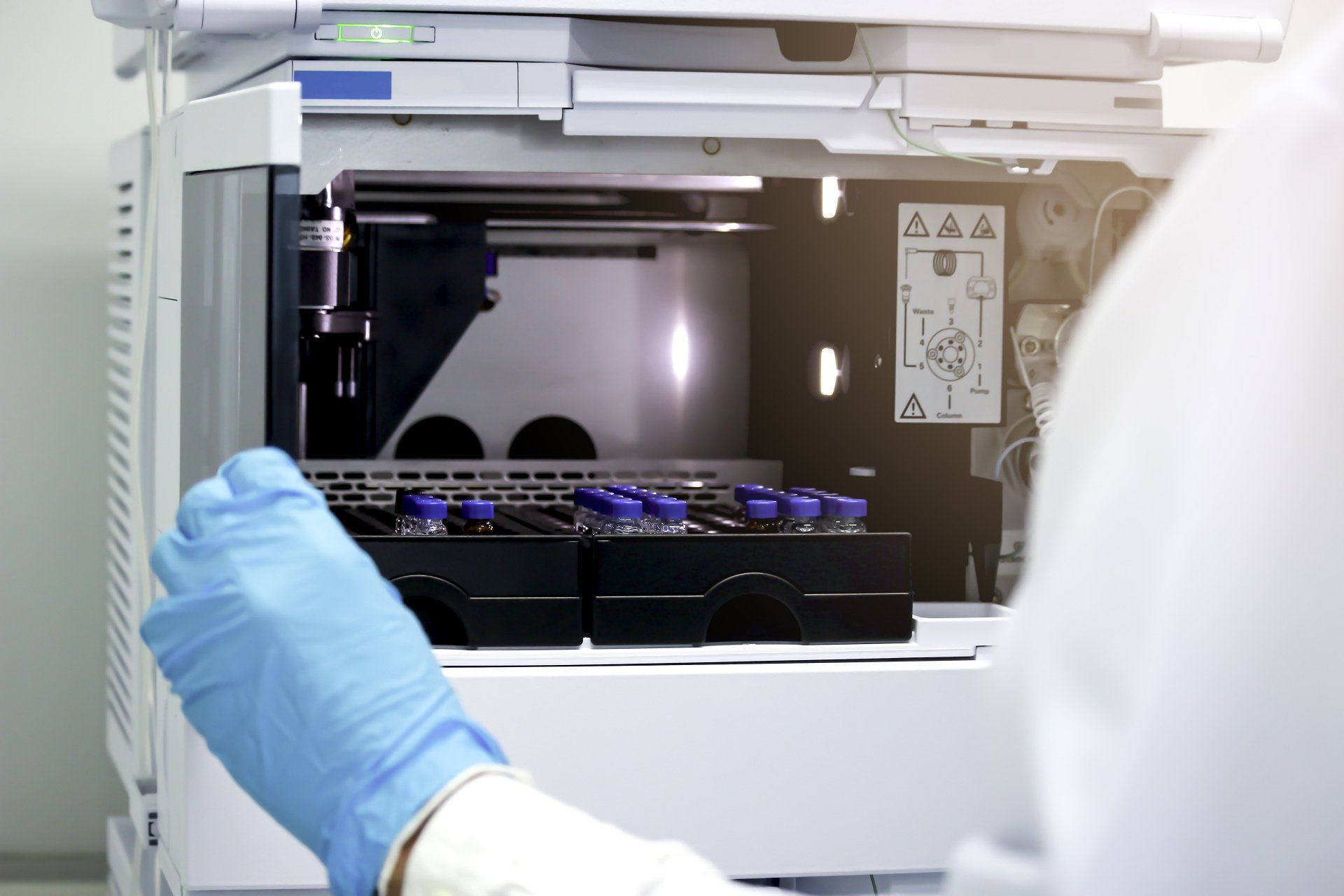

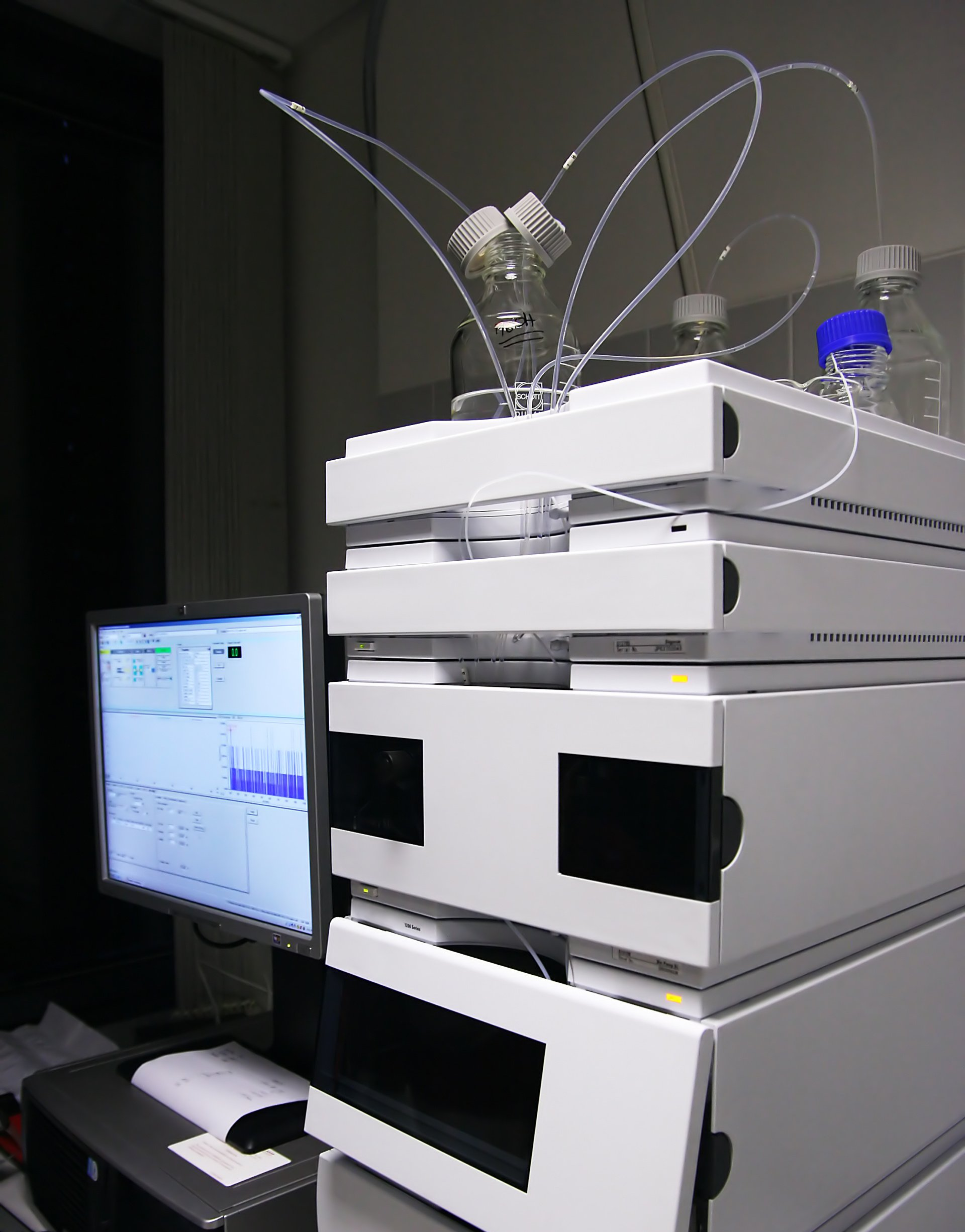

High performance liquid chromatography, also referred to HPLC, a technique in analytical chemistry used to separate, identify, and quantify each component in a mixture. This highly sensitive instrument needs to be serviced and maintained properly. To achieve the most accurate results, contamination prevention is crucial. Here are some ways to maximize your HPLC instrumentation's reliability and accuracy.

Storing and Handling Additives and Solvents

Because solvents and additives are the critical ingredients in HPLC analysis, the way they are stored and handled is a crucial responsibility. Solvents should be stored in their original bottle. This is typically either borosilicate glass or surface treated amber. When you transfer to a different container you increase the chance of contamination. Leaching alkalines and silica can form adducts in your analytes if you use soda-lime or clear glass bottles. Plastic materials including beakers, funnels, bottles, and gloves can all leach plasticizers, anti-slipping agents and stabilizers, so aside from syringes or pipette tips, these should also be avoided.

Maintaining the HPLC System

The better your HPLC system is organized, the higher the sensitivity you can achieve. Minimizing the amount of dead volume is a crucial consideration. Dead volume is the total of all your system parts between the detector cell and the injector. Peak broadening, splitting, and tailing can create poor resolution. Poor resolution prevents the detection of low-abundant analytes.

Replacing the filter every month or two will protect the system and column from excess debris, as well as lower the baseline noise.

Maintaining the HPLC Column

Depending on detection technique, sample size, and load ability, your HPLC column size dimensions can vary. If you opt for a smaller diameter size you can scale flow rate and injection volume, while improving sensitivity. The chromatographic column is a frequent source of contamination. The negative effects of a column bleed can be mitigated by implementing a washing protocol.

Overall Solvents and Additives Maintenance

Solvents and additives are an essential part of the HPLC process. Solvents from water, methanol, isopropanol, and acetonitrile to additives like acids, buffers and bases enable the analysis to take place.

Properly Maintaining Lab Assets

Laboratory equipment cleanliness is essential to maintaining an accurate and accommodating laboratory. If contamination is noticed, flushing with MS grade solvents can properly clean the equipment.

Maintaining a clean laboratory from the inside out of each asset is essential to continuing to produce the accurate results you need. Overbrook is an experienced, skilled, and educated provider of laboratory equipment services, especially when it comes to HPLC instrumentation.