Relocation Services for Material Testing Labs: Relocation Planning Stages

Ted Palashis | November 15, 2021

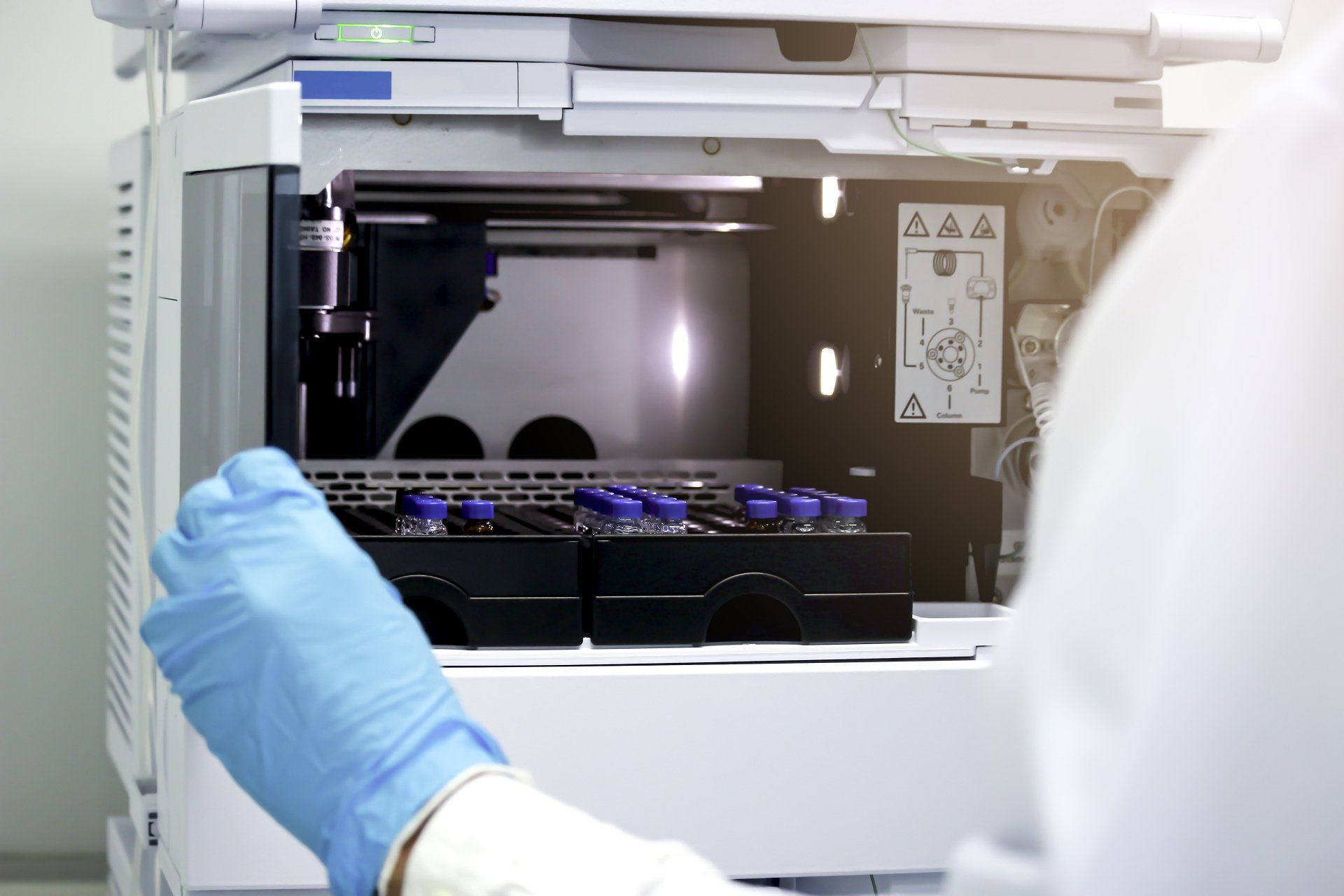

Material testing labs perform various tasks that influence and improve products and services across a wide array of sectors. These studies, data, and information play a critical role in the constant evolution of how things are made and used. As material testing laboratories grow, relocation to bigger, newer, and better facilities is necessary; but these moves can not come at the expense of discovery and results. Let’s take a closer look at the stages that create an effective, efficient, and successful laboratory relocation.

The Laboratory Relocation Exploratory Stage

During the exploratory stage, your relocation manager will submit and review and a list of assets, as well as the determined scope of work. A site audit with the client and OSS team will also be performed. During this time, a preliminary project timeline and benchmarks will also be determined.

The Laboratory Relocation Commitment Stage

During the commitment stage, the submission of preliminary cost estimates, as well as the contract, is presented.

The Laboratory Relocation Move Preparation Stage

One of the most critical steps in the relocation process is the preparation stage. During this time, a secondary review of the timeline and milestones will be performed. The hierarchy of mission-critical assets and placement will be identified. The site’s considerations in terms of facilities and IT will be reviewed. Packing protocols will be discussed with all technicians. Instruments and their components will be inventoried.

Compliancy documentation will be identified and handled. Lastly, the confirmation of site-ready preparedness at both the original and new locations will be established.

The Laboratory Relocation De-Installation Stage

Before any asset can be removed and relocated, it needs to be benchmarked for performance, de-installed, and packed.

Once these steps are accurately and expertly taken, the instrumentation can be moved to the new location.

The Laboratory Relocation Re-Installation Stage

At the new site, each asset can be unpacked and reinstalled. At this point in time, your relocation management partner will qualify, benchmark, and validate each asset.

The experienced team of project managers and engineers at Overbrook understands that managing a laboratory relocation is a full-time job with specific skill sets appropriate to the organizational, engineering, facilities, compliance, and experiential tasks required. With their proven track record of strategic planning and execution, you can avoid budget overruns, missed deadlines, and costly downtime.